Actually might be harder than you think! There are many things that you’ve got if you’re living where you’ve been living for a long time. Once you move to a new location, you’ll find yourself without things you didn’t even know you had.

In my moving around I learned a few things about myself. Three things I absolutley need to be happy.

1. a safe place to live

2. something to do with my time (usually a job)

3. friends to call and hang out with

1. Place to live

There have been two or three occasions where I “sold everything and moved.” One of them was out to the Big Island of Hawaii. My brother and I moved out there, and while we knew one guy and his family, essentially we didn’t know anyone. We arrived with only a couple of bags of clothes, and had packed up some things from our last house and mailed them to ourselves there. Jensen and I rented this total dump of a house for $750/month, three bedroom house. There were two of us, and we wanted another roommate, making rent a reasonable $250/month each. Here’s a pic of the house on the left.

So, Jensen and I got the house sorted out. It was empty! No furnishings. We had a kitchen and no silverware. We had a living room, and no place to sit. I had this picture that I can’t find of Jensen and I sitting on a box throwing cards into a hat in an empty living room. Our stuff was in boxes, but we didn’t have anyplace to put the stuff even if we unpacked the boxes. The picture struck a cord with me because we were in an empty white room. We had no furniture. We were in a town where we didn’t know anyone. I remember that striking home with me: I didn’t have anyone to call even if I wanted to. I didn’t have a job to go to. We had nothing there at all.

Sitting in that empty room, throwing cards into a hat was a learning moment. This is what happens when you take everything away and start fresh.

2. something to do with you time

The easiest and most obvious thing here is a JOB. You gotta get a job to pay rent because the savings you moved here with is dwindling. I was hitting the job market hard. I had nothing else going on, so I dedicated most of my day to getting a job. Even in a little town like Hilo, there were some jobs to be had. Nothing that paid much, but at my portion of rent $250/mo, I didn’t need much.

How about school? Another great thing to be doing in a new place. Your days will have purpose. You will have someplace you need to be, things you need to do. I’m no zen master. In fact, if I don’t have anything going on, I will start making stuff up. And those “projects” can often be pretty useless. But I like doing things, it feels good.

School and job easily segues into the third part:

3. friends

Imagine going to a job, and coming home. Your home is comfortable. You’ve got internet, a TV, maybe a goldfish and a couple of potted plants that need watering from time to time. You get home, check your blogs, and go to sleep. Next morning, wake up, go to that job, come home, repeat. For me, that is a frustrating cycle. I need people to talk to, joke with and hang out with. When I work a job, it’s usually so I can have a little money to spend on the weekend, gas money for camping, or movies, or other stuff. My job is important, but the people I meet are more important.

Another place I sold it all and moved to was Bozeman Montana. I showed up in that town with one friend, and again, didn’t know a soul except the person I went there with. I knew that even though I liked this person a lot, I needed more people. I looked around for a restaurant job. Waiters are witty, chatty, night owls who are good with strangers and probably don’t have day jobs. I looked around for a busy restaurant in town with young people and took a good look at the other employees. Would I like to be friends with these people? I did, so I applied, and it all worked out great.

Yet another time I sold everything and moved to California with my now wife, we both got jobs. I made some decent friends at a restaurant I worked at, and school I was attending. Alison got a job at REI. She said it was because she’d worked at an REI before, and it was easy to transition there. REI doesn’t pay worth a damn, like any other run of the mill retail job. But the people, now they are special. Alison and I went on all sorts of adventures with her true friends that she made at work.

If you don’t like people you work with, and haven’t found any groups to participate in (did you look at meetup.com? I’ve had success there), then cold calling is an option. I think this is easier for boys because we’ve had to do cold calls for quite some time. We learned by hitting on women. Think of it like you’re hitting on girls, but instead, hit on dudes. You size them up, does this dude look like the kind of person I want to be a friend? Then chat him up. It’s really that easy, and difficult!

I met one of my favorite roommates in just this way. I was working at a pancake house in Hilo, and there was this dude with a giant backpack who was taking up one of my booths. I got to chatting to him, and turned out he was looking for a place to rent in town. I had just the place. I made a date with him for beers later, and we hit it off right away. Rick, Jensen and I were all a terrific match, and had some really great times for a whole year at Barenaba Ln. You can imagine that story either way where Rick was a girl, and she and I ended up dating, so wonderful! Or, Rick turned out to be a cool guy and a wonderful roommate, also wonderful! The process I used was the same. Albeit a different end-game 😉

How about you…

Does selling it all and moving appeal to you? Have you ever done it before?

What sorts of things do you need for basic functioning? How about to function and have a good time every once and a while.

Get to know yourself a little better by trying to take a step back. You are already a complex person with needs, if you know it or not. You’ve already done a lot of this work already, you just need to identify it. Dig up some old photos and start looking at different parts of your life.

In these photos, where were you? Mountains, beach, hot, cold, city, suburbs, water, desert. Do you remember being happy there, or miserable? (both are helpful) What did your daily life look like when that picture was taken? How about your weekends or vacations. What sort of job did you have? Like it, hate it, tolerate it? Did you make friends at that job?

Look at pictures of you with friends. Where did you meet them? How close were you with them? How long did it take for you to become close with them? Friends don’t fall off trees. (Hopefully they don’t)

Ideally, friendships would start natural, unforced, comfortable, organic. Unless you grow up with someone, how else is it going to start? It’s okay to start off awkward. Generally people seek connection with others. When you first meet someone it seems forced, awkward, shallow, and it probably IS. Once you start to develop some rapport with them, some stories, and share some experiences together, it will start becoming more natural.

Side note here. Maslow’s Hierarchy of Needs. Dude circa 1934 answered these questions on his own and wrote a book. Here they are from him:

- Biological and Physiological needs – air, food, drink, shelter, warmth, sex, sleep.

- Safety needs – protection from elements, security, order, law, limits, stability, freedom from fear.

- Social Needs – belongingness, affection and love, – from work group, family, friends, romantic relationships.

- Esteem needs – achievement, mastery, independence, status, dominance, prestige, self-respect, respect from others.

- Self-Actualization needs – realizing personal potential, self-fulfillment, seeking personal growth and peak experiences.

To wrap up

Moving to a new place is hard! You may have an easy time of it where “things just fall into place,” but those things that fall into place are still important. For the times when it doesn’t work out, you can approach it from a more cognitive side. You gotta identify those magic things, and make them happen. You’ll know if something is missing because you’ll be miserable, or sad, or uncomfortable. Things won’t feel right. Use that as an opportunity to learn about yourself: what are your needs, and how can you meet them?

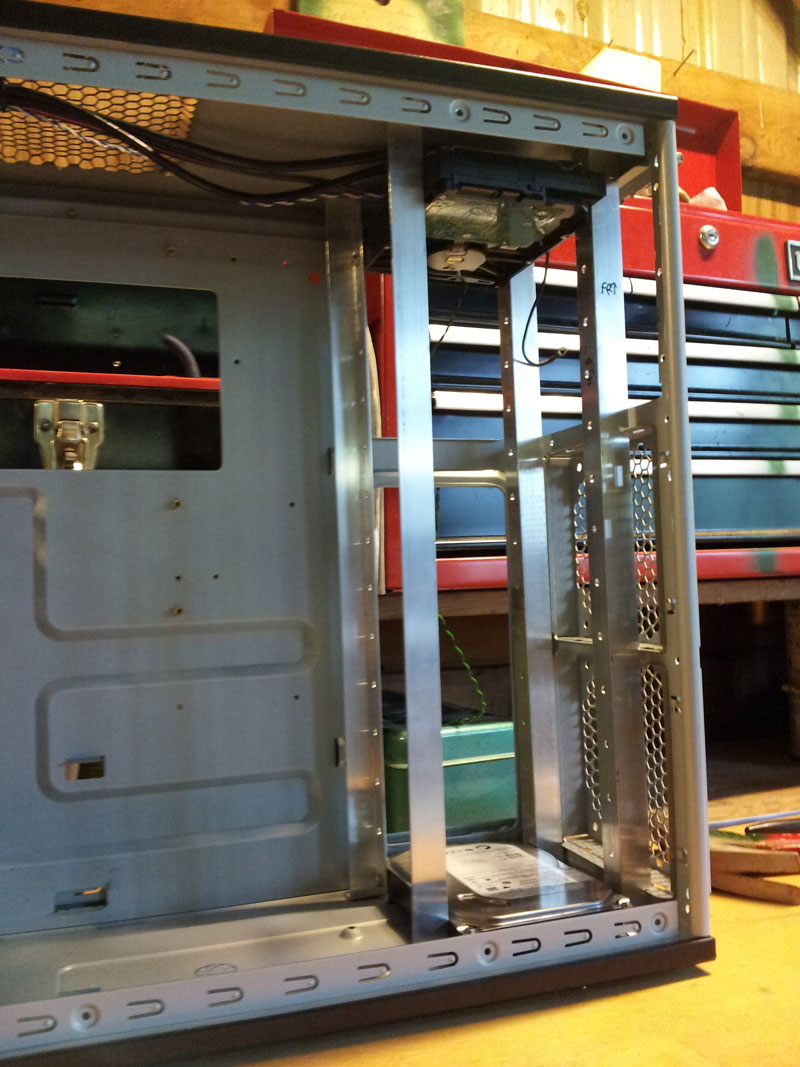

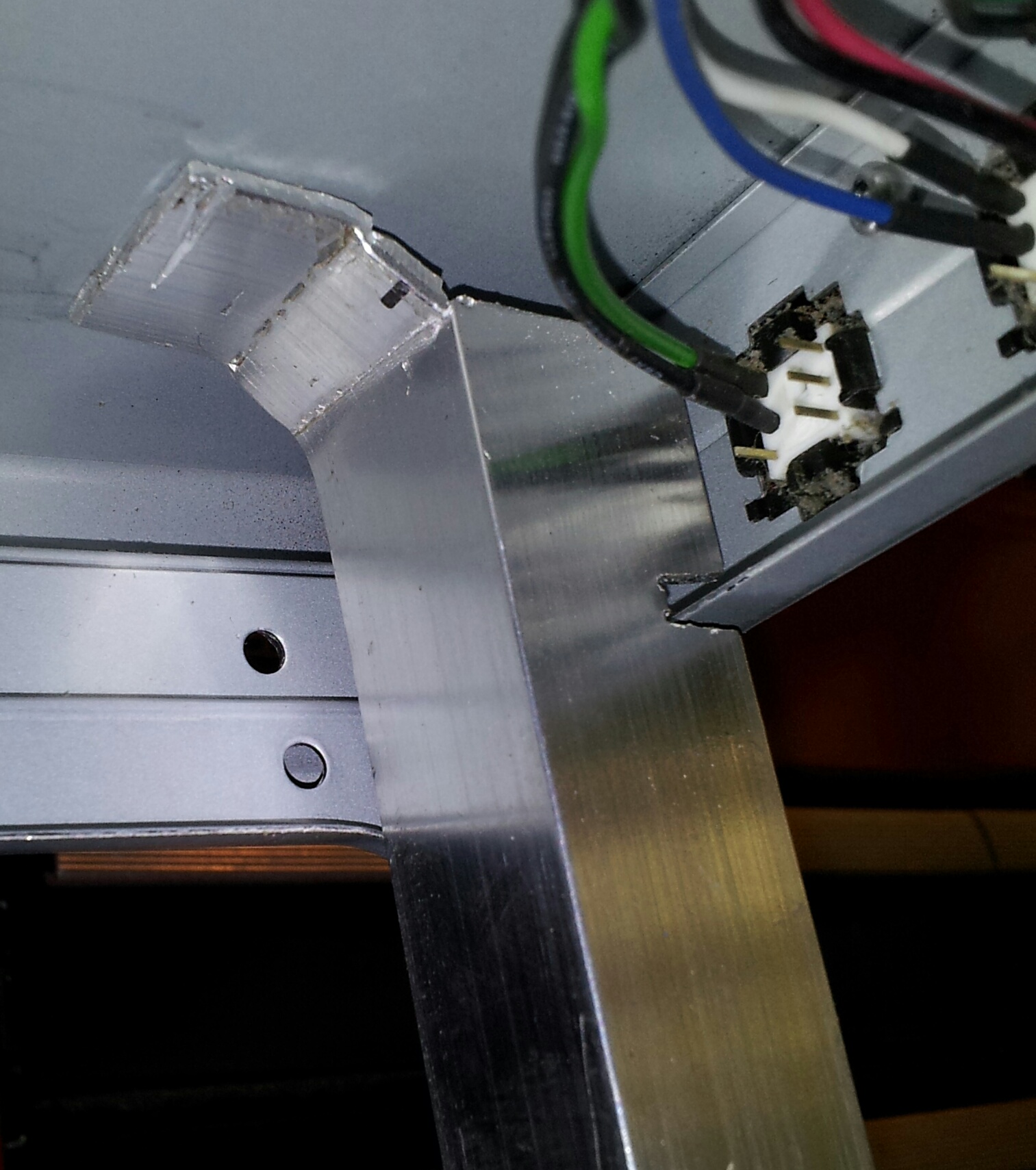

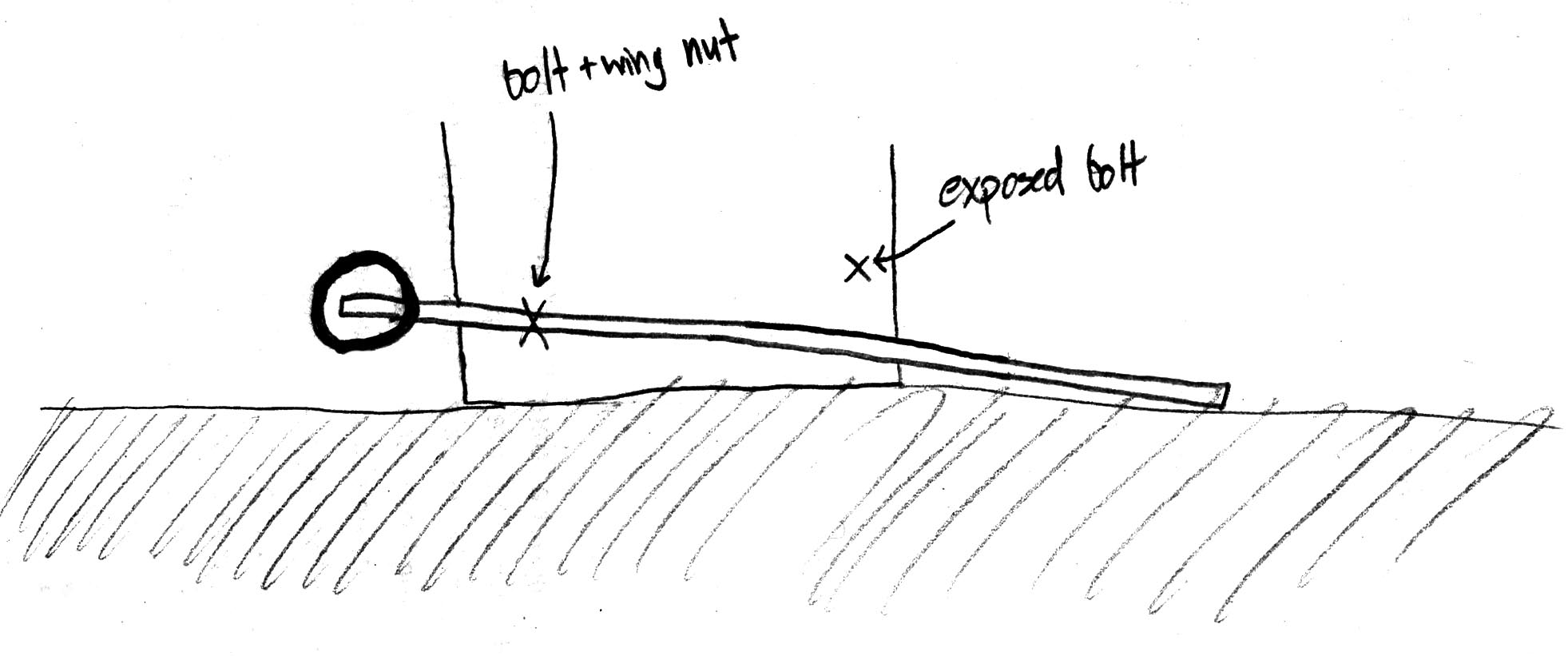

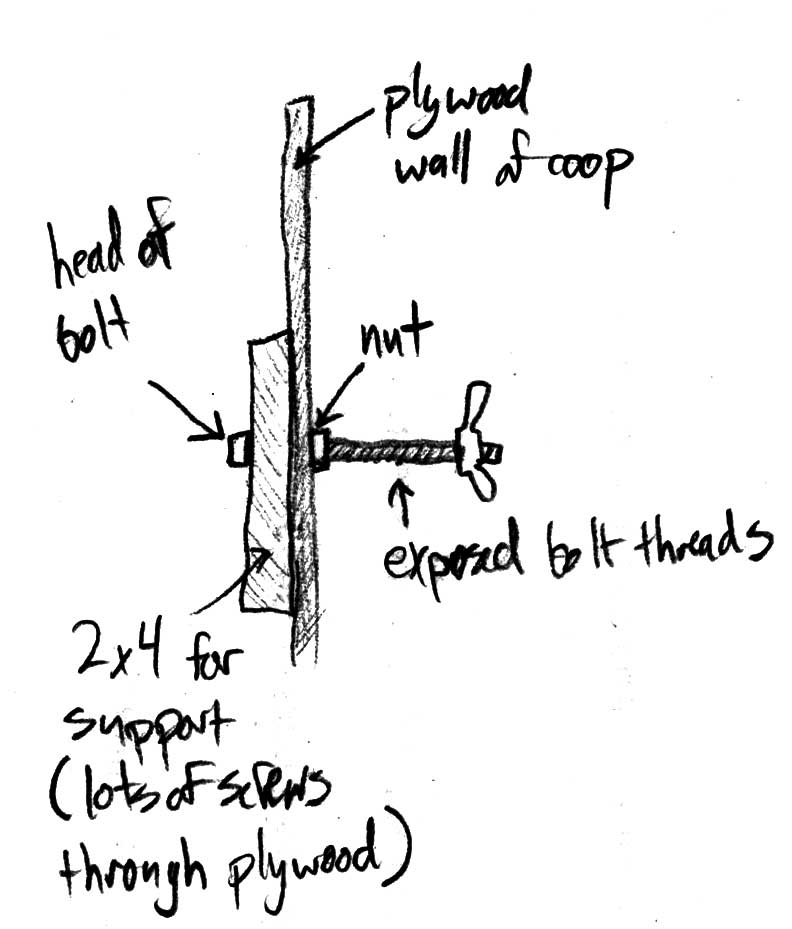

You can also see a little notch I made in the bar to accommodate some other bits of the case. You can gouge yours out as needed.

You can also see a little notch I made in the bar to accommodate some other bits of the case. You can gouge yours out as needed.

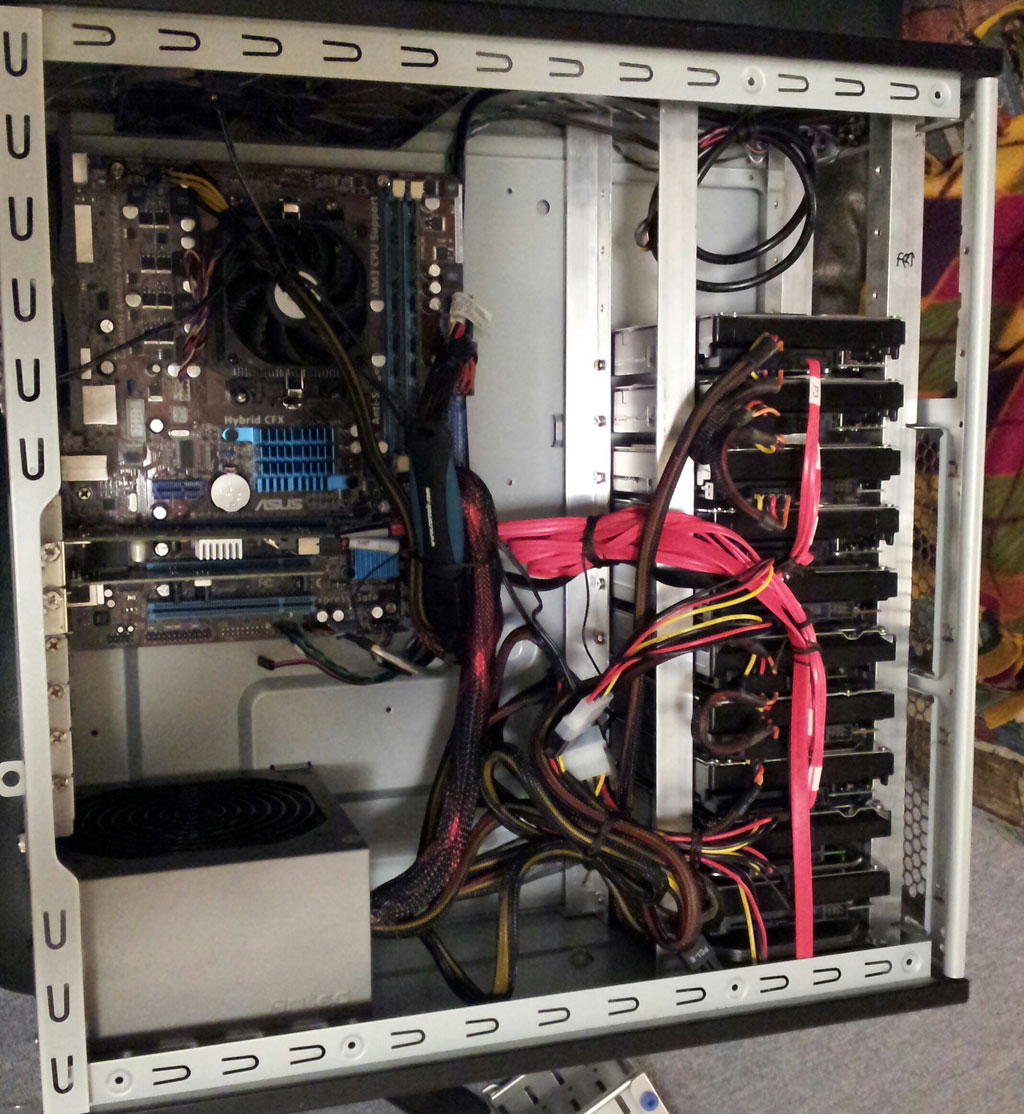

In this coop below, I used 2x4s which ended up being very very heavy! Resist the urge to build a coop like a house, and make it for chickens. No problemo.

In this coop below, I used 2x4s which ended up being very very heavy! Resist the urge to build a coop like a house, and make it for chickens. No problemo.

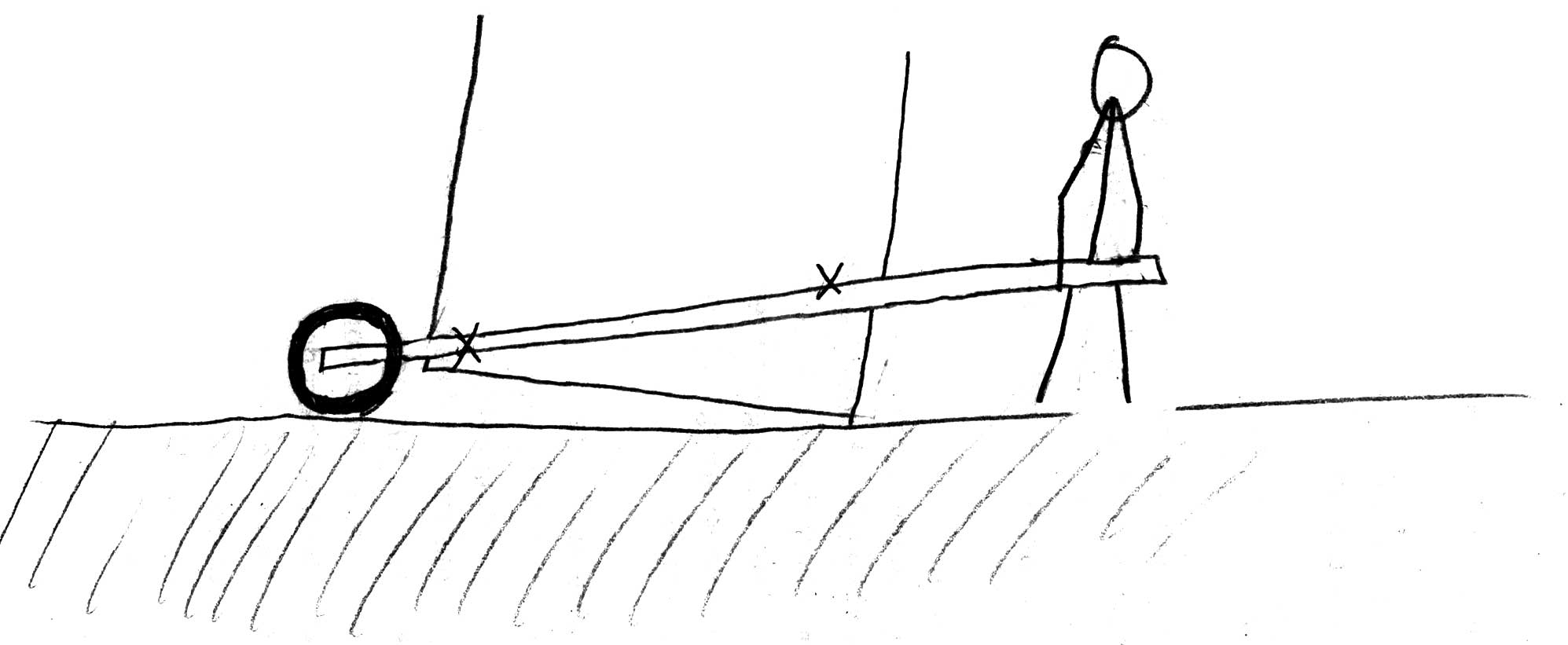

At this point, there isn’t much getting around the fact that you have to lift that coop off the ground like a cart. It would be better to have the wheels closer to the center taking more of that load, short of getting out a jack to put on the wheels, I didn’t think that up.

At this point, there isn’t much getting around the fact that you have to lift that coop off the ground like a cart. It would be better to have the wheels closer to the center taking more of that load, short of getting out a jack to put on the wheels, I didn’t think that up.

wheels wanted to torque to the side. I put together a yoke to hold the wheels from torquing. I also added an additional 2×4 up front for the people to hold on to as they pull it around. Now, the coop is essentially surrounded by a 2×4 rectangle that can also lift the coop. It’s a little hard to tell from this picture, but the 2×4 on the bottom extends all the way across to the other wheel. This worked very well.

wheels wanted to torque to the side. I put together a yoke to hold the wheels from torquing. I also added an additional 2×4 up front for the people to hold on to as they pull it around. Now, the coop is essentially surrounded by a 2×4 rectangle that can also lift the coop. It’s a little hard to tell from this picture, but the 2×4 on the bottom extends all the way across to the other wheel. This worked very well. opener from

opener from  17 birds and they all have to use four boxes. Should be fine. The design feature in this part is a double hinge door. For the first hinge, it opens from the top down. You can open the hatch from the outside to reach in and grab eggs which will be an everyday occurrence. Secondly, if you undo the additional clasps on the side, you use the lower most hinge. Doing this, the entire wall falls away leaving an open edge to the nest box. Then you can easily scrape the entire contents onto the ground. Boom, done. Also of note – the floor of the nest box is the only floor in the entire coop. Less to clean: yay!

17 birds and they all have to use four boxes. Should be fine. The design feature in this part is a double hinge door. For the first hinge, it opens from the top down. You can open the hatch from the outside to reach in and grab eggs which will be an everyday occurrence. Secondly, if you undo the additional clasps on the side, you use the lower most hinge. Doing this, the entire wall falls away leaving an open edge to the nest box. Then you can easily scrape the entire contents onto the ground. Boom, done. Also of note – the floor of the nest box is the only floor in the entire coop. Less to clean: yay!